On March 12, 2016, I went to the airport with the intention of doing 3 takeoffs and landings to warm the oil for the engine’s first oil change. Taxi out and runup went fine. Oil pressure in the 50’s during idle and in the 70’s during fast taxi. The first takeoff and landing went fine with oil pressure in the 70’s and 80’s. But during taxi back for the 2nd takeoff, the oil pressure sensor went off scale high very rapidly. I considered shutting down in the runup block, but all other parameters seemed normal so I thought it would be safe to taxi back to the hangar for diagnosis.

During the taxi back to the hangar, the gauge continued to read off scale high. At the hangar, I shut down the engine, and didn’t think to check the gauge before powering off the avionics. I then reapplied power to the avionics with the engine off and noted the gauge had returned to zero.

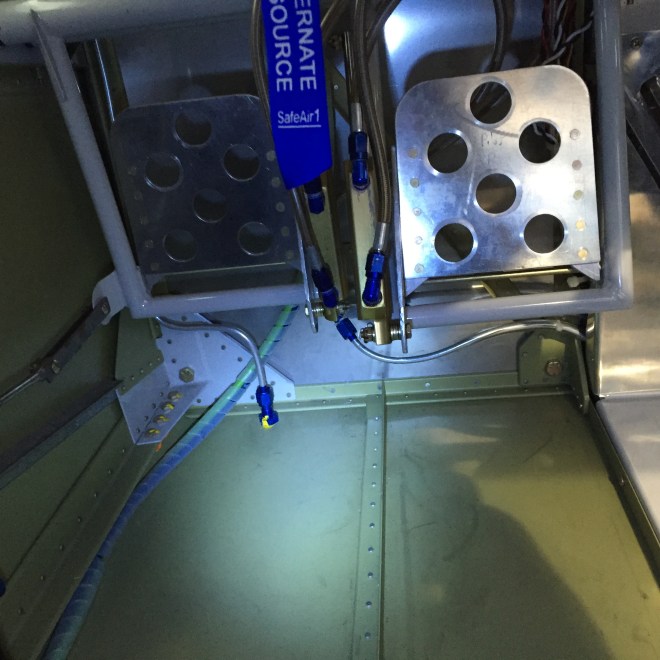

The Kavlico oil pressure gauge, is a 3-wire device with red, black, and green wires. The red wire is +5V supply from the avionics, the black wire is ground, and the green wire is sensor output. I learned from reading that 0.5 volts out is likely 0 PSI, and 4.5 volts out is likely 150 PSI. Downloading the data showed that when it went off scale high it was reading 154 PSI. This might be an indication the output wire was getting shorted to the +5V.

I disconnected the wiring to the sensor on the firewall forward side and checked all connections for security and/or damage.

0.5 Engine Time, 1.0 Total Time (11.6/13.5 Cumulative)