Disconnected the hoses and unscrewed the elbow fittings from two master cylinders (lower fittings on pilot & passenger right brake pedals). Resealed 2 brake pedal NPT fittings using permatex #2 and reconnected the Bonaco hose fittings.

Bled the right side brake (for probably the 5th time).

Removed the upper cowl.

Removed the lower cowl.

Trimmed metal flange on left side of starter ring gear to make getting the lower cowl on and off easier.

Installed cowl inlet baffle seals on the lower cowl lips using #6 countersunk screws and all metal locknuts and washers. I used 3/32 blue silicone for the first time from Aircraft Spruce.

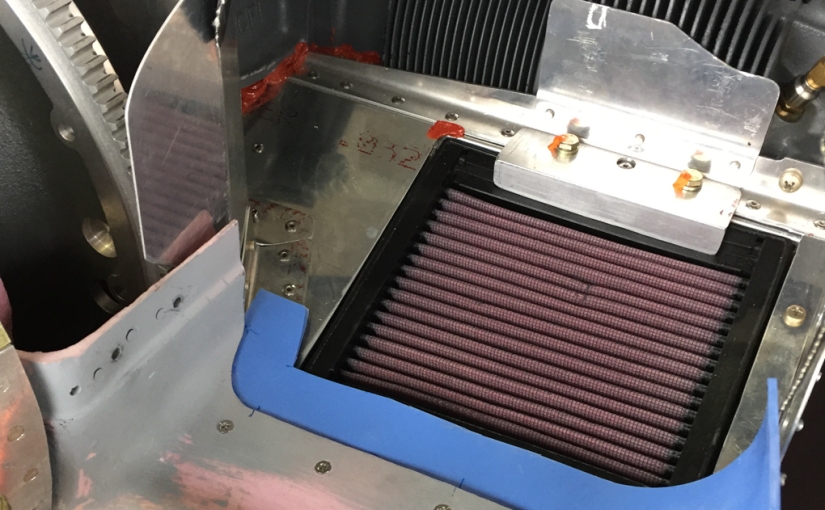

Front left lower cowl air inlet baffle seal:

Front right lower cowl air inlet baffle seal

New piece of black baffle material added at the front on both sides like this one on the left:

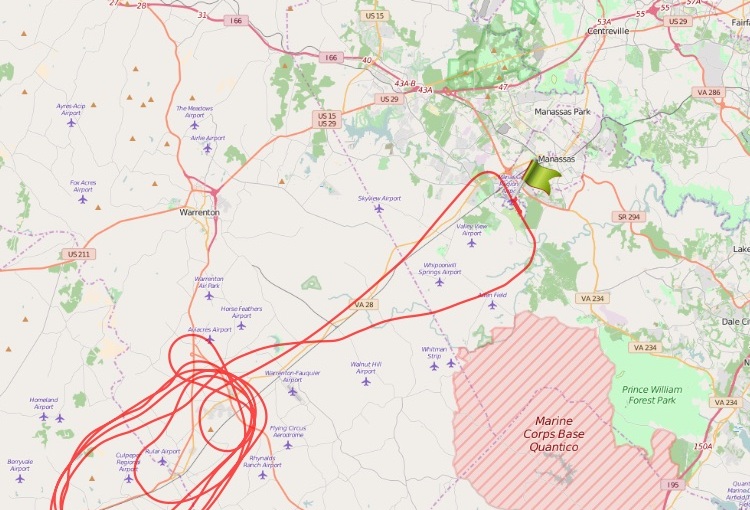

Found an area on the lower cowl in front of the nose gear leg that is obviously letting a bunch of pressurized air into the lower cowl area. This is probably reducing cooling of the CHTs to some extent. I will try covering this hole on the next flight. It eventually will get covered by the nose gear fairing upper intersection fairing (but I haven’t made that yet).